The SCADA (Supervisory Control and Data Acquisition) intelligent system realizes automated production, intelligent monitoring, data analysis, and remote management in concrete mixing plants, improving production efficiency, ensuring quality, and reducing operating costs.

1. System architecture

The SCADA intelligent system adopts a three-tier architecture of "PLC+SCADA+cloud platform":

Equipment level sensors (weighing, temperature, pressure), PLC (controlling mixers, conveyors, valves, etc.), frequency converters

Control layer SCADA server (data acquisition, logic control), HMI (human-machine interaction interface)

Management layer cloud platform (data analysis, remote monitoring), ERP/MES (production management), mobile end (APP/WeChat)

2. Core functions

(1) Intelligent production control

automatic batching

Real time monitoring of the weight of raw materials such as cement, sand and gravel, water, and additives to ensure accurate proportioning (error ≤ ± 1%).

Automatically compensate for humidity (such as adjusting the water volume when the moisture content of sand and gravel changes).

Optimization of mixing process

Automatically adjust the mixing time and speed according to the type of concrete (C30/C50).

Monitor current and temperature to prevent overload or material blockage.

(2) Real time monitoring and alarm

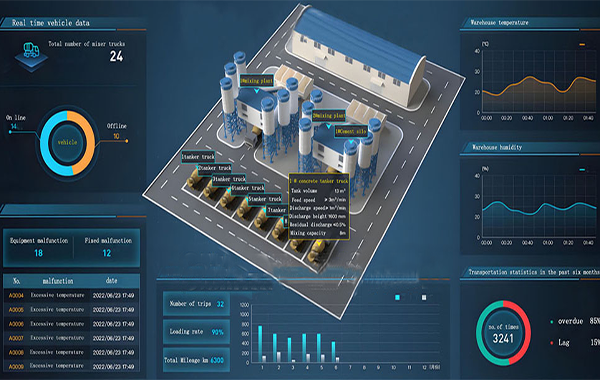

Visual Kanban

Dynamically display production status (running/faulty/standby), inventory levels, and equipment parameters (temperature, vibration).

3D virtual simulation provides an intuitive view of device operation.

Intelligent alarm

Graded alarms (warning, general, emergency) are pushed to mobile phones, computers, or sound and light alarms.

Automatically record the cause of faults to assist in quick repairs.

(3) Quality traceability and analysis

batch management

Record the mix proportion, production time, operator, and quality inspection data of each batch of concrete, and support QR code traceability.

quality analysis

Compare laboratory strength data and optimize the mix proportion (such as reducing cement dosage by 5% to still meet the standard).

(4) Predictive maintenance

Equipment health monitoring

Analyze motor vibration and bearing temperature to provide early warning of faults.

maintenance plan

Automatically generate maintenance tasks (such as lubrication cycle, filter replacement).

(5) Energy and Cost Management

Energy consumption monitoring

Statistics on electricity, water, and gas consumption, optimizing production scheduling (avoiding peak electricity prices).

Cost analysis

Calculate the raw materials, energy consumption, and labor costs for each square meter of concrete to identify space savings.

(6) Remote management and mobile devices

Cloud platform+APP

Mobile/computer remote start stop device, adjust parameters, receive alarms.

Support WeChat/SMS notifications, allowing managers to keep track of production status at any time.

3. Key technologies

Technical application

Industrial Internet of Things (IIoT) sensor data acquisition, 5G/WiFi/4G remote transmission

Big data analysis optimizes ratio, predicts equipment failures, and conducts energy-saving analysis

AI vision detection and recognition of aggregate particle size and foreign objects (such as plastic and metal) to avoid blockage

4. System advantages

✅ Improve efficiency: automate production, reduce manual intervention, and increase production capacity by 20% -30%.

✅ Quality assurance: Accurate proportioning, strength qualification rate ≥ 99%, reducing the risk of material return.

✅ Reduce costs: Predictive maintenance reduces downtime, energy optimization saves 10% -15% on electricity bills.

✅ Intelligent management: remote monitoring on mobile phones/computers, data-driven decision-making.