Details

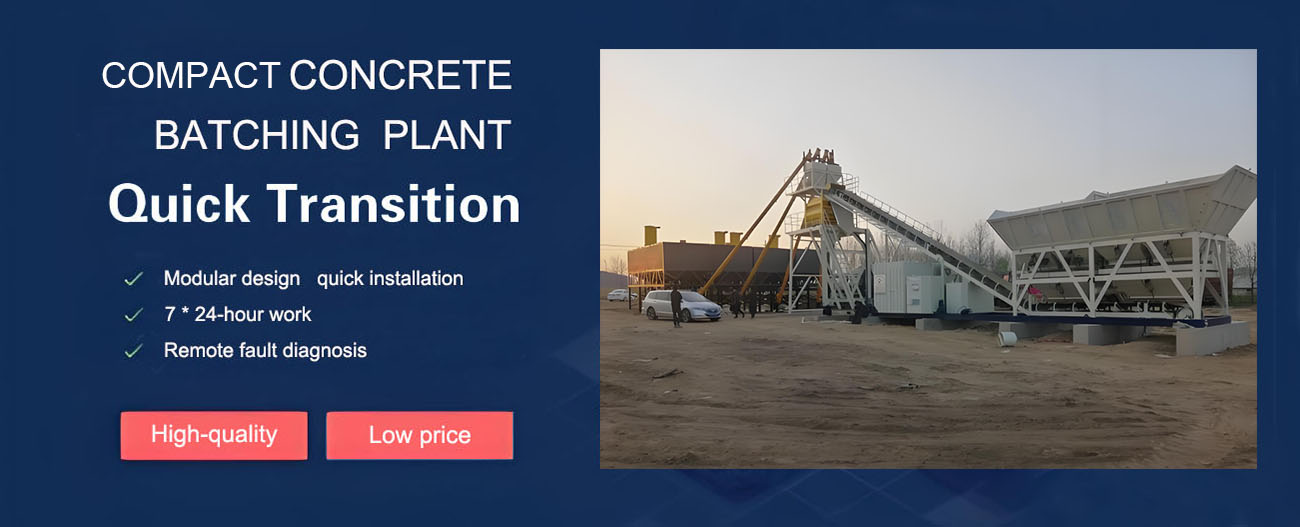

Compact concrete batching plants, quick installation in 7 days, including models 60, 90, 120, etc., with a production capacity of 50-120m ³/h. The compact concrete batching plants adopts modular and foundation free design. The modular pre installation of ingredients, conveying, metering, and mixing systems effectively reduces the volume of sea transportation while minimizing the footprint, facilitating quick on-site installation and production, significantly reducing the need for on-site foundation construction and hoisting, and suitable for small and medium-sized projects with small sites and close distances.

Technical Parameter

| Model |

HZS60 |

HZS90 |

HZS120 |

HZS180 |

HZS240 |

HZS270 |

| Mixer |

Model |

JS1000 |

JS1500 |

JS2000 |

JS3000 |

JS4000 |

JS4500 |

| Discharge volume(L) |

1000L |

1500L |

2000L |

3000L |

4000L |

4500L |

| Aggregate size(mm) |

≤60mm |

≤80mm |

| Batch station |

Bin volume(m³) |

15×4 |

20×4 |

| Belt width of inclined belt conveyor |

Trough belt B800 |

Trough belt B1000 |

flat belt B1200 |

| Scale rang & accuracy |

Stone scale(kg) |

(360-1200)±2% |

(540-1800)±2% |

(720-2400)±2% |

(1080-3600)±2% |

(1440-4800)±2% |

(1620-5400)±2% |

| Sand scale(kg) |

(240-800)±2% |

(360-1200)±2% |

(480-1600)±2% |

(720-2400)±2% |

(960-3200)±2% |

(1080-3600)±2% |

| Cement scale(kg) |

(180-600)±1% |

(270-900)±1% |

(360-1200)±1% |

(540-1800)±1% |

(720-2400)±1% |

(810-2700)±1% |

| Fly ash scale(kg) |

(60-200)±1% |

(90-300)±1% |

(120-400)±1% |

(180-600)±1% |

(240-800)±1% |

(270-900)±1% |

| Water scale(kg) |

(90-300)±1% |

(150-500)±1% |

(240-800)±1% |

(360-1200)±1% |

| Additve scale(kg) |

(15-50)±1% |

(24-80)±1% |

(36-120)±1% |

| Discharging height(m) |

4m |

4.2m |

Highlights

Customized aggregation bin options

The aggregate bin is the production starting point of the concrete mixing plant, providing flexible options to meet your needs. Choose 60m ³ (4x15m ³) or 80m (4x2m ³) inline silos for independent measurement. Effectively support your production of large volume concrete.

|

Maximum efficiency of power and precision

A sturdy mixer cylinder manufactured using fully automatic welding robots; Even within a short mixing time, it maintains a high degree of uniformity. High alloy wear-resistant parts can produce various types of concrete (pre mixed concrete, precast concrete, roller compacted concrete, etc.). |

Simple setup on zero ground

Due to the newly developed steel leg system, mobile concrete mixing plants can be directly installed on the ground without the need for special concrete foundations. This innovative design provides significant cost advantages and reduces installation costs.

|

Maximum efficiency of power and precision

A sturdy mixer cylinder manufactured using fully automatic welding robots; Even within a short mixing time, it maintains a high degree of uniformity. High alloy wear-resistant parts can produce various types of concrete (pre mixed concrete, precast concrete, roller compacted concrete, etc.). |

Applicable scenarios

Since 1998, Jinheng Machinery has been dedicated to the design and manufacturing of high-quality concrete mixing plants, covering an area of approximately 80000 square meters and employing 260 workers. Obtained CE, SGS, and ISO certifications successively.

The heavy-duty steel structure design, multi-layer anti-corrosion treatment, and global procurement of accessories ensure the durability and longevity of the mixing plant. It has been exported to over 80 countries in Europe, America, Asia, and Africa.

Concrete mixer: BHS (Germany) Gearbox: Flender (Germany) Motor: ABB/(Switzerland) Spiral conveyor/butterfly valve/vibration motor: WAM (Italy)

Weighing sensor: Mettler Toledo (USA) Bearing: SKF (Sweden) Cylinder/solenoid valve: AIRTAC (Taiwan) Electrical components: Schneider (France)

We have designed multiple models to meet the needs of different projects and clients

1. Quick loading, container assembled concrete batching plant

2. Foundation free concrete batching plant

3. Compact concrete batching plant

4. Mobile concrete batching plant

5. Tower type concrete batching plant

6. Precast concrete batching plant

7. UHPC batching plant

8. Large smart concrete batching plant

9. Dry powder mortar mixing plant

10. Small cement production line (new product)

Please contact us to learn about the most suitable concrete mixing plant solution for your needs.

Service and Guarantee

Here are some of our customization options. Our technical sales team can support you in assiting the appropriate layout and equipment to optimize your productivity and business.

1、Concrete recycling system integration

Are you still throwing away your concrete waste or faulty production? As the importance of environmental responsibility of businesses increases, certain standards are being introduced in production in order to leave a cleaner world to future generations. In addition, in today's world where production costs are gradually increasing, operational efficiency has become the most important heading of sustainable activities. With the JINHENG recycling unit, components such as aggregate, sand and water in concrete can be separated and reused in production.

2、Equipment and applications that ensure the most efficient operation in different climatic conditions.

Special reinforcement and applications for quality and uninterrupted concrete production in harsh winter conditions: Steam pipes placed inside the aggregate bunker Complete enclosure of the main unit with 40 mm thick insulated panels Complete covering of the bottom of the aggregate bunker with 40 mm thick insulated panels Retractable electric gates on the aggregate bunker Steam generator (high performance steam generators that can run on diesel, natural gas or both, selected according to the plant capacity)

3、Concrete batching plant coating applications

The top and sides of the aggregate bunker can be covered with trapezoidal sheets to both protect from environmental influences (rain, snow, wind, etc.) and to minimize the impact of dusting on the environment. The four sides and top of the main unit, which contains the mixer, cement-water-additive scales and aggregate waiting bunker, can be covered with trapezoidal sheets. In this way, the main unit can be protected from environmental influences (rain, snow, wind, etc.).

4、Fiber feed system integration

You can improve the versatile production capacity of your batching plant thanks to the fiber feeding system that automatically feeds and doses steel or polyester concrete fibers used in the production of special quality concrete and is integrated with the plant automation.

5、DISCOVER MORE

The plant you want with dozens of additional options-

HYDRONIX brand Microwave moisture meter for aggregate bunker sand compartment. It precisely measures the moisture in the sand and ensures that less water and complementary sand is added by the amount of moisture measured by the automatic system.- Aggregate Bunker bunker grates to be placed on top of the bunker with 100x 100 mm mesh width to prevent large stones from entering and damaging the system- High pressure automatic cleaning system for mixers- Mixer working monitoring system-Mixer safety interlock can be added for more safety during maintenance. With this system consisting of two switches, the plant cannot be started unless the maintenance person stops the system completely and takes one switch on himself, preventing possible accidents.