Details

The precast concrete batching plants provide high-quality and effective solutions for the precast industry that requires concrete.

Special solutions include a stepped concrete batching plant, aggregate storage silos and mixers arranged side by side, as well as a tower concrete batching plant. The aggregate storage bin is located above the mixing device. One or more mixers of different capacities can be configured, and customized designs and specific transfer methods can be made based on the factory layout and product type.

Prefabricated concrete batching plant is used to produce prefabricated concrete components, such as concrete pipes, concrete pavers, lightweight panel walls, etc.

Technical Parameter

| Model |

HZS50 |

HZS75 |

HZS100 |

HZS150 |

| Theoretical productivity(m³/h)(Calculated by C30 ordinary commercial concrete) |

50 |

75 |

100 |

150 |

| Mixer |

Planetary |

Model |

JN1000 |

JN1500 |

JN2000 |

JN3000 |

| Discharge volume (L) |

1000 |

1500 |

2000 |

3000 |

| Discharge gate numbers |

1 or 2 |

1 or 2 or 3 |

| Aggregate size (mm) |

≤60 |

| Planetary |

Model |

JN1000 |

JN1500 |

JN2000 |

JN3000 |

| Discharge volume (L) |

1000 |

1500 |

2000 |

3000 |

| Discharge gate numbers |

1 or 2 |

| Aggregate size (mm) |

≤60 |

≤80 |

| Batching station (semi-under ground type) |

Bin volume (m³) |

15×4 |

20×4 |

30×4 |

| Conveyor capacity of inclined belt conveyor(t/h) |

450 |

500 |

600 |

| Scale range & accuracy |

Stone scale (kg) |

(400-1200)±2% |

(600-1800)±2% |

(800-2400)±2% |

(1200-3600)±2% |

| Sand scale (kg) |

(250-800)±2% |

(400-1200)±2% |

(500-1600)±2% |

(800-2400)±2% |

| Cement scale (kg) |

(200-600)±1% |

(300-900)±1% |

(400-1200)±1% |

(600-1800)±1% |

| Cement scale (kg) |

(60-200)±1% |

(100-300)±1% |

(130-400)±1% |

(200-600)±1% |

| Water scale (kg) |

(100-300)±1% |

(150-500)±1% |

(150-500)±1% |

(250-800)±1% |

| Additive scale (kg) |

(15-50)±1% |

| Dischargeheight (m) |

According to the project requirement |

Highlights

No shovel type aggregate yard

Small footprint, no hardened courtyard;

Aggregate feeding, no need for shovel loading;

Intelligent dust removal and energy conservation and environmental protection;

Low investment cost and fast website construction time.

|

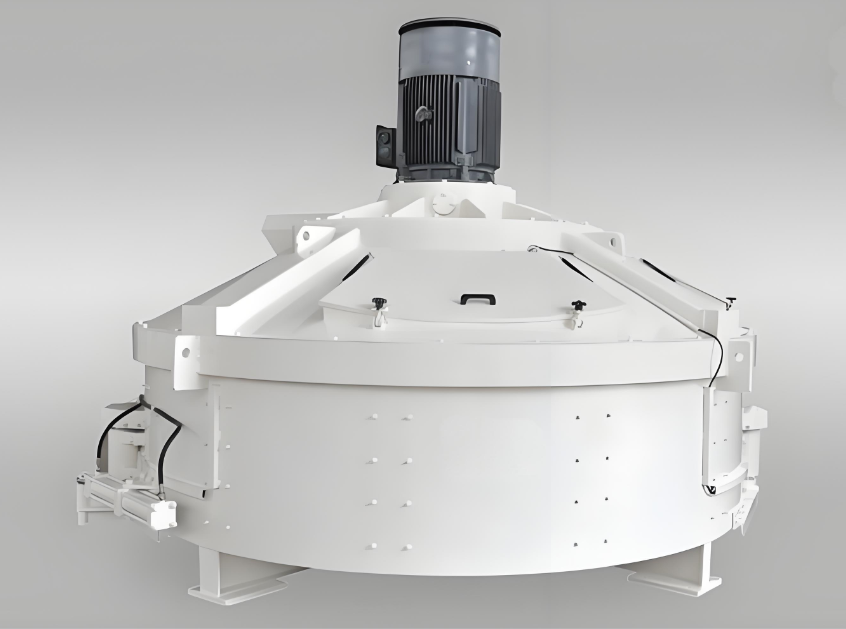

Vertical axis planetary mixer

Smooth transmission, low noise, high torque, and strong durability;

Mixing evenly, without any dead corners, and the movement rules cover the entire mixing bucket;

High pressure flushing device, 360 degree spiral nozzle;

Fast unloading speed, flexible configuration of 1-3 unloading doors;

|

Concrete Travelling Buckets

The speed of the high-speed concrete moving bucket is 1 meter per second;

Equipped with mixing function to prevent concrete segregation or hardening;

Mobile bucket can achieve climbing and turning functions; |

New Type Control System

Weighing deduction and supplementary weighing functions;

Circular batching improves production efficiency;

Software porting can be directly copied and used;

Automatically retrieve and classify orders, quickly filter orders;

The channels and AD channels can be freely changed and exchanged;

|

Applicable scenarios

Since 1998, Jinheng Machinery has been dedicated to the design and manufacturing of high-quality concrete mixing plants, covering an area of approximately 80000 square meters and employing 260 workers. Obtained CE, SGS, and ISO certifications successively.

The heavy-duty steel structure design, multi-layer anti-corrosion treatment, and global procurement of accessories ensure the durability and longevity of the mixing plant. It has been exported to over 80 countries in Europe, America, Asia, and Africa.

Concrete mixer: BHS (Germany) Gearbox: Flender (Germany) Motor: ABB/(Switzerland) Spiral conveyor/butterfly valve/vibration motor: WAM (Italy)

Weighing sensor: Mettler Toledo (USA) Bearing: SKF (Sweden) Cylinder/solenoid valve: AIRTAC (Taiwan) Electrical components: Schneider (France)

We have designed multiple models to meet the needs of different projects and clients

1. Quick loading, container assembled concrete batching plant

2. Foundation free concrete batching plant

3. Compact concrete batching plant

4. Mobile concrete batching plant

5. Tower type concrete batching plant

6. Precast concrete batching plant

7. UHPC batching plant

8. Large smart concrete batching plant

9. Dry powder mortar mixing plant

10. Small cement production line (new product)

Please contact us to learn about the most suitable concrete mixing plant solution for your needs.

Service and Guarantee

Here are some of our customization options. Our technical sales team can support you in assiting the appropriate layout and equipment to optimize your productivity and business.

1、Concrete recycling system integration

Are you still throwing away your concrete waste or faulty production? As the importance of environmental responsibility of businesses increases, certain standards are being introduced in production in order to leave a cleaner world to future generations. In addition, in today's world where production costs are gradually increasing, operational efficiency has become the most important heading of sustainable activities. With the JINHENG recycling unit, components such as aggregate, sand and water in concrete can be separated and reused in production.

2、Equipment and applications that ensure the most efficient operation in different climatic conditions.Special reinforcement and applications for quality and uninterrupted concrete production in harsh winter conditions: Steam pipes placed inside the aggregate bunker Complete enclosure of the main unit with 40 mm thick insulated panels Complete covering of the bottom of the aggregate bunker with 40 mm thick insulated panels Retractable electric gates on the aggregate bunker Steam generator (high performance steam generators that can run on diesel, natural gas or both, selected according to the plant capacity)

3、Concrete batching plant coating applicationsThe top and sides of the aggregate bunker can be covered with trapezoidal sheets to both protect from environmental influences (rain, snow, wind, etc.) and to minimize the impact of dusting on the environment. The four sides and top of the main unit, which contains the mixer, cement-water-additive scales and aggregate waiting bunker, can be covered with trapezoidal sheets. In this way, the main unit can be protected from environmental influences (rain, snow, wind, etc.).

4、Fiber feed system integrationYou can improve the versatile production capacity of your batching plant thanks to the fiber feeding system that automatically feeds and doses steel or polyester concrete fibers used in the production of special quality concrete and is integrated with the plant automation.

5、

DISCOVER MOREThe plant you want with dozens of additional options-

HYDRONIX brand Microwave moisture meter for aggregate bunker sand compartment. It precisely measures the moisture in the sand and ensures that less water and complementary sand is added by the amount of moisture measured by the automatic system.- Aggregate Bunker bunker grates to be placed on top of the bunker with 100x 100 mm mesh width to prevent large stones from entering and damaging the system- High pressure automatic cleaning system for mixers- Mixer working monitoring system-Mixer safety interlock can be added for more safety during maintenance. With this system consisting of two switches, the plant cannot be started unless the maintenance person stops the system completely and takes one switch on himself, preventing possible accidents.