Details

The Jinheng containerized mixing plant adopts a modular structure, which can achieve modular installation. The equipment modules are quickly connected by bolts, and each layer of modules can be assembled on the ground and then lifted and spliced as a whole. Its internal pipelines are pre installed before leaving the factory, and only quick connectors and quick connections are needed on site. Other components also adopt modular design, such as batching stations and aggregate conveyor belts, which have the characteristics of small footprint, fast installation, and convenient transportation. The powder warehouse adopts a sheet-like design and factory production to avoid uncontrollable quality caused by on-site welding, while also achieving batch stocking and rapid delivery.

This containerized mixing plant is not only capable of producing high-quality ready mixed concrete, but also a long-term investment. The weighing unit, hopper, and equipment components are all designed with heavy-duty steel structures (which can be hot-dip galvanized) to enhance durability. Whether it is ready mixed concrete, roller compacted concrete or precast concrete, container mixing plants can produce efficiently.

This device has strong adaptability and is packaged in a container. The three highlights of the strong adaptability of container mixing plants are safe and reliable installation, strong wind resistance, and transferability and reusability.

Technical Parameter

Container type Concrete Batching Plant Technical Specifications

-

Type CHZS60 CHZS90 CHZS120 CHZS180 CHZS240

- Concrete Mixer JS1000 JS1500 JS2000 JS3000 JS4000

- Aggregate batching system PLD1600 PLD2400 PLD3200 PLD4800 PLD6400

- Maximum aggregate size ≤60mm ≤60mm ≤80mm ≤80mm ≤80mm

- Mixing cycle 60S 60S 60S 60S 60S

- Production capacity 60m³/H 90m³/H 120m³/H 180m³/H 240m³/H

- Power 120KW 150KW 180KW 220KW 280KW

Highlights

Unloading hopper

The unloading hopper has a larger angle and volume, and does not stick to the material.

The unloading hopper can store 1 tray of material without any dripping or leakage.

Intelligent unloading, no need to frequently adjust the unloading time of the mixer.

Zero drops enter the mixer truck without overflowing or splashing. The mixer unloads at full speed to improve productivity. |

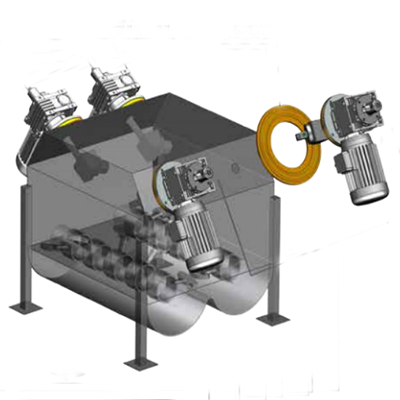

Concrete mixer

Extend the discharge door by 15%, reduce residual materials by 50%, and implement an automated high-pressure cleaning system;

Anti lock shaft design reduces cleaning frequency;

Negative pressure valve: Maintain no negative pressure difference inside and outside the mixer to reduce measurement interference.

Monitoring system: Visualize the internal mixing status of the mixer and adjust the aggregate in a timely manner.

|

Intelligent powder silo

Anti leakage warehouse: dual loading level alarm protection to avoid material waste and environmental accidents;

Error prevention: Implement intelligent allocation of weighing scales and powder feeding ports to avoid incorrect feeding;

Explosion proof warehouse: Intelligent linkage between feeding port access control and dust collector to avoid warehouse explosion;

Remaining material measurement: The surface mount level gauge monitors and measures the remaining amount of the powder silo in real-time; |

Smart control system

Automatic weighing deduction and supplementary weighing function; Self learning correction, no need for manual settings.

After each material is unloaded, the next batch of ingredients is immediately prepared, greatly reducing the batching time and improving production efficiency;

The porting of control software does not require installation and can be directly copied and used;

Automatic retrieval and classification function for task orders, facilitating quick screening of task orders;

The input/output channels and AD channels can be changed freely, and some hardware damage does not affect normal production;

|

Applicable scenarios

Jinheng containerized concrete mixing plant is mainly favored by companies that require high concrete production capacity. These green leaves hope to use the factory in the same area for a long time in order to comfortably produce concrete in a wide area, thanks to its flexibility in configuration and layout.

Jinheng has nearly 30 years of experience in this field, designing and manufacturing containerized concrete mixing plants using innovative and technological methods. In this regard, Jinheng has designed and manufactured containerized concrete mixing plants that are as modular as possible, making them easier to transport and shorter to install compared to similar concrete mixing plants.

The Jinheng containerized concrete mixing plant is equipped with an aggregate hopper. After weighing during batch production, the required materials are stored on top of the mixer. Therefore, the mixing plant ensures maximum production efficiency for users by saving cycle time.

According to demand, the aggregate batching machine can be equipped with 3, 4, 5, 6 or even more compartments to use different types of aggregate materials according to demand. In addition, depending on the installation area, transfer conveyors or buckets can also be used to transport the aggregates to the mixer.

Jinheng installs containerized concrete mixing plants at the installation site to maximize savings and improve production efficiency, and designs concrete mixing plants specifically according to the site layout when necessary.

Please contact us to learn about the most suitable concrete mixing plant solution for your needs

Service and Guarantee

Here are some of our customization options. Our technical sales team can support you in assiting the appropriate layout and equipment to optimize your productivity and business.

1、Concrete recycling system integration

Are you still throwing away your concrete waste or faulty production? As the importance of environmental responsibility of businesses increases, certain standards are being introduced in production in order to leave a cleaner world to future generations. In addition, in today's world where production costs are gradually increasing, operational efficiency has become the most important heading of sustainable activities. With the JINHENG recycling unit, components such as aggregate, sand and water in concrete can be separated and reused in production.

2、Equipment and applications that ensure the most efficient operation in different climatic conditions.

Special reinforcement and applications for quality and uninterrupted concrete production in harsh winter conditions: Steam pipes placed inside the aggregate bunker Complete enclosure of the main unit with 40 mm thick insulated panels Complete covering of the bottom of the aggregate bunker with 40 mm thick insulated panels Retractable electric gates on the aggregate bunker Steam generator (high performance steam generators that can run on diesel, natural gas or both, selected according to the plant capacity)

3、Concrete batching plant coating applications

The top and sides of the aggregate bunker can be covered with trapezoidal sheets to both protect from environmental influences (rain, snow, wind, etc.) and to minimize the impact of dusting on the environment. The four sides and top of the main unit, which contains the mixer, cement-water-additive scales and aggregate waiting bunker, can be covered with trapezoidal sheets. In this way, the main unit can be protected from environmental influences (rain, snow, wind, etc.).

4、Fiber feed system integration

You can improve the versatile production capacity of your batching plant thanks to the fiber feeding system that automatically feeds and doses steel or polyester concrete fibers used in the production of special quality concrete and is integrated with the plant automation.

5、DISCOVER MORE

The plant you want with dozens of additional options-

HYDRONIX brand Microwave moisture meter for aggregate bunker sand compartment. It precisely measures the moisture in the sand and ensures that less water and complementary sand is added by the amount of moisture measured by the automatic system.- Aggregate Bunker bunker grates to be placed on top of the bunker with 100x 100 mm mesh width to prevent large stones from entering and damaging the system- High pressure automatic cleaning system for mixers- Mixer working monitoring system-Mixer safety interlock can be added for more safety during maintenance. With this system consisting of two switches, the plant cannot be started unless the maintenance person stops the system completely and takes one switch on himself, preventing possible accidents.